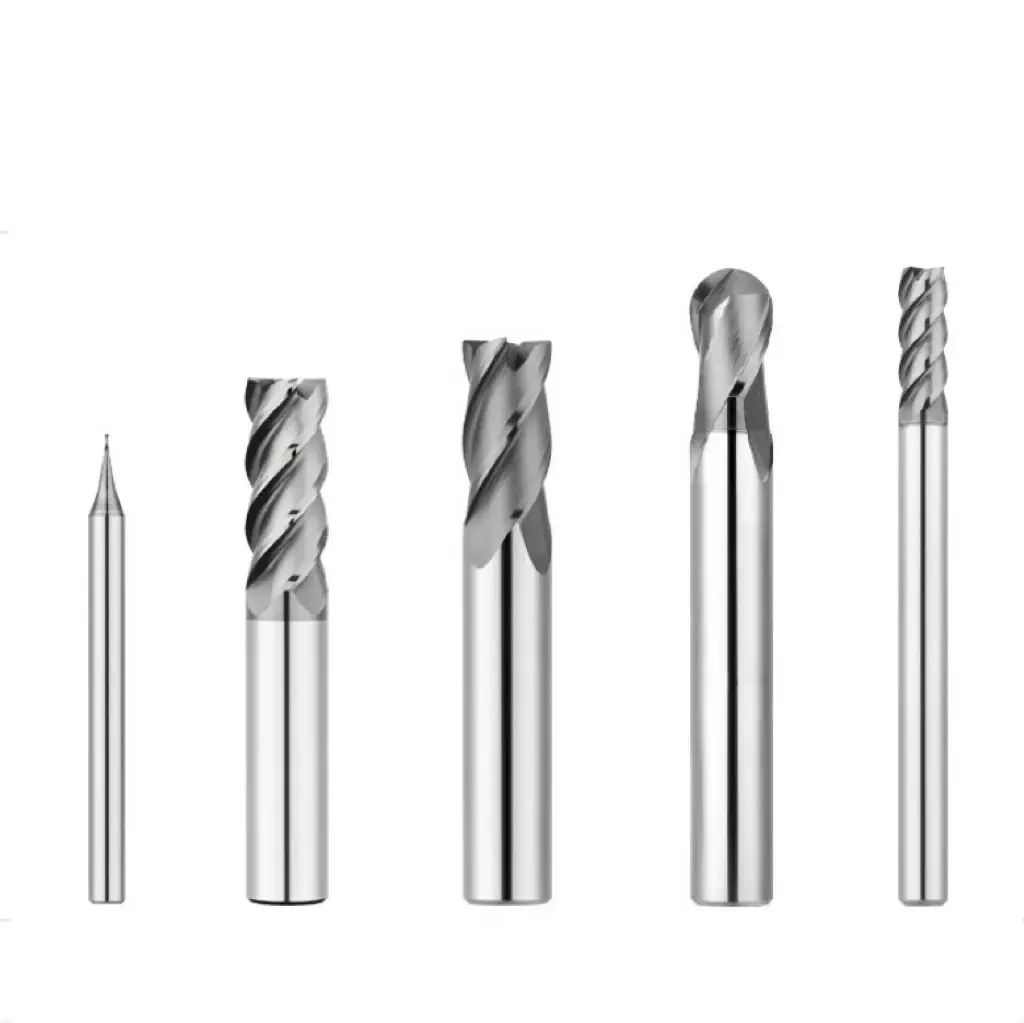

Premium 4-Flute Nano Black Coated End Mill | High Hardness Tungsten Carbide CNC Milling Cutter for Stainless Steel, Aluminum <000000> Hard Metals

Product Information

Upgrade your CNC machining with our 4-flute nano black coated end mill, engineered for superior performance on stainless steel, aluminum, and hard metals. The tungsten carbide substrate ensures exceptional hardness (HRC 55+), while the nano-scale black coating reduces friction and heat, minimizing tool wear and extending service life. Its balanced 4-flute design delivers smooth chip evacuation and precise cuts, ideal for roughing, finishing, and contouring in die/mold making, aerospace, and automotive industries. Compatible with high-speed machining centers, this mill offers excellent surface finish (Ra ≤ 0.8μm) and dimensional accuracy, boosting productivity and reducing downtime. Trusted by professionals for reliable, consistent results in tough machining applications.

Products Advantages

key Features&Benefits

Our nano black coating technology stands out with a dense, ultra-hard layer (1500+ HV) that resists abrasion, adhesion, and chemical corrosion, outlasting standard coatings by 30% in high-temperature environments (up to 1200°C). The 4-flute geometry balances rigidity and chip flow, enabling aggressive feeds/speeds without compromising precision, perfect for deep slots and complex profiles Versatile across materials—from soft aluminum to hardened steels (HRC 50)—it eliminates the need for multiple tools, saving inventory costs. Engineered with a precise helix angle (30°) for reduced cutting forces, it ensures quieter operation and lower vibration, enhancing workpiece quality. Backed by strict quality control (100% precision inspection), this mill delivers unmatched durability and efficiency, making it a top choice for high-volume production and demanding CNC applications. Maximize output while maintaining tight tolerances with this premium machining solution.

Product parameters

Product name | tungsten solid carbide endmill |

Product blade number | 4 blades |

Product coating | Nano coating |

Suitable material | Stainless steel, alloy steel, die steel, steel plate, etc. |

Suitable equipment | CNC machining center, engraving machine and other milling machines |

Details

User Instructions

1. Information Required by Buyers for Choosing Tools and Operating Instructions

2.Before using the tool, please measure the tool's deflection. If the deflection exceeds 0.01 mm, correct it before cutting.

3.The shorter the length of the tool extending out of the chuck, the better. If the tool extends too long, reduce the rotational speed, feed rate, or cutting volume.

4.During cutting, if abnormal vibrations or sounds occur, reduce the rotational speed and cutting volume until the situation improves.

5.For steel cooling, spray cooling or jet cooling is preferred, which can enhance the performance of the milling cutter.

FAQS

Usually we can ship within 5-7 days for small quantity, and about 30 days for large quantity.