Customizedcarbide Endmill

Product details of the carbide endmill

Product Information

Premium raw materials: ATW CNC carbide endmill is made of high-quality materials which undergo strict screening before entering the factory. These materials are proven to be of high quality regarding production. Our strict quality control throughout the whole production process greatly guarantees the quality of the product. After many years of development, DONGGUANG ULTRA MICRO HARDWARE MECHINERY CO.,LTD has been recognized by customers for its good reputation and excellent quality.

Product Information

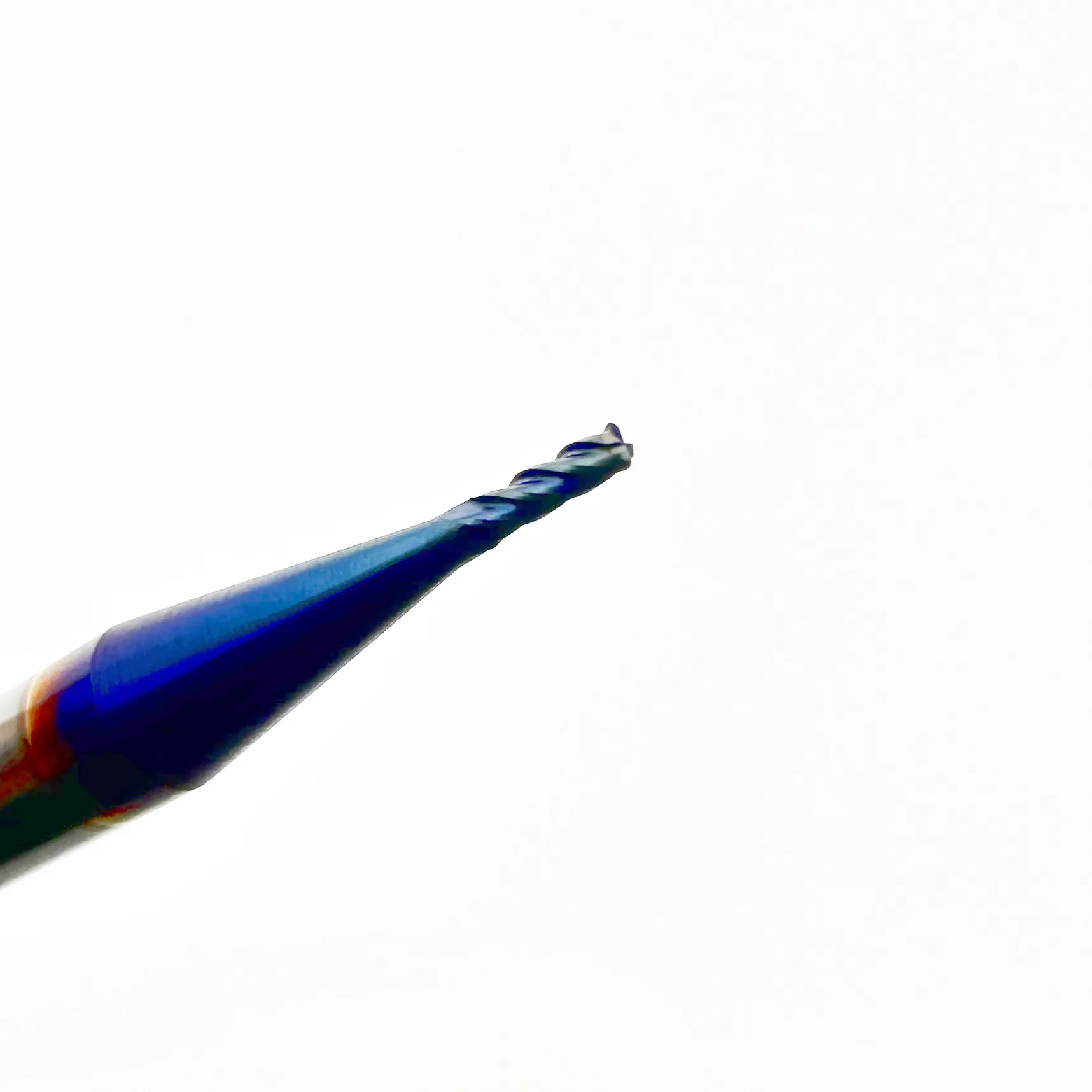

This 4 Flute Blue Nano Coated Corner Radius End Mill is designed for precision machining of corners, fillets, and bevels in tough materials like steel, titanium, and hardened alloys (HRC 50+). The nano ceramic coating provides exceptional hardness (3000 HV) and heat resistance, reducing friction and extending tool life by 40% compared to standard coatings. The 4-flute design ensures efficient chip evacuation at high feed rates, ideal for both roughing complex contours and finishing sharp transitions. Engineered with a precision-ground corner radius, it delivers smooth surface finishes (Ra ≤ 0.8μm) in aerospace, automotive, and mold-making applications, supporting both wet and dry machining for versatile industrial use.

Products Advantages

key Features&Benefits

• Nano Coating Technology: Boosts hardness, heat resistance, and corrosion protection, targeting searches for "nano-coated corner radius tools" and "high-temperature machining."

• 4 Flute Design: Optimizes material removal for fast roughing while maintaining stability for precise finishing, appealing to manufacturers needing efficiency and accuracy.

• Specialized Geometry: Perfect for corner radius, fillets, and bevel machining—keywords like "corner radius end mill," "contour machining," and "mold making tools" drive niche traffic.

• Wide Material Compatibility: Works with steel, titanium, stainless steel, and hardened alloys, covering high-demand industrial materials.

Product parameters

|

Product name |

66HRC tungsten solid carbide corner radius endmill |

|

Product blade number |

4 blades |

|

Product coating |

Nano blue coating |

|

Suitable material |

45°~55° stainless steel |

|

Suitable equipment |

CNC machining center, engraving machine and other milling machines |

Details

FAQS

Company Advantage

• Our company has established a complete testing center and introduced advanced testing equipment. Our products not only meet the customer's quality requirements, but also have the advantages of reliable performance, no deformation, and durability.

• Our global manufacturing and sales network have spread to and other overseas countries. Inspired by the high marks by the customers, we are expected to expand our sales channels and provide more considerate service.

• Our team members have strong design and production capacity to complete product design and mold development in a short period of time. So, we can provide you with the most professional custom services.

• There are multi main traffic lines passing through our company's location and the developed traffic network makes for the supplies distribution.

• Since established, we have spent years of efforts in the development and production of the hardware. So far, we have mature craftsmanship and experienced workers to help us achieve a highly efficient and reliable business cycle

All electric equipment is produced and directly sold from the factory. The price is favorable without reference price. In addition, you could enjoy discounts for larger order. Please contact ATW CNC to place orders if in need.