ATW CNC Cnc Carbide Tools M8*1.25*8D*70L*P2Supply

Product details of the cnc carbide tools

Product Introduction

The design of cnc carbide tools is frequently renovate with modern technology. It is certified under laws and regulations. The product is in high demand at home and abroad thanks to its considerable economic benefits.

Product Description

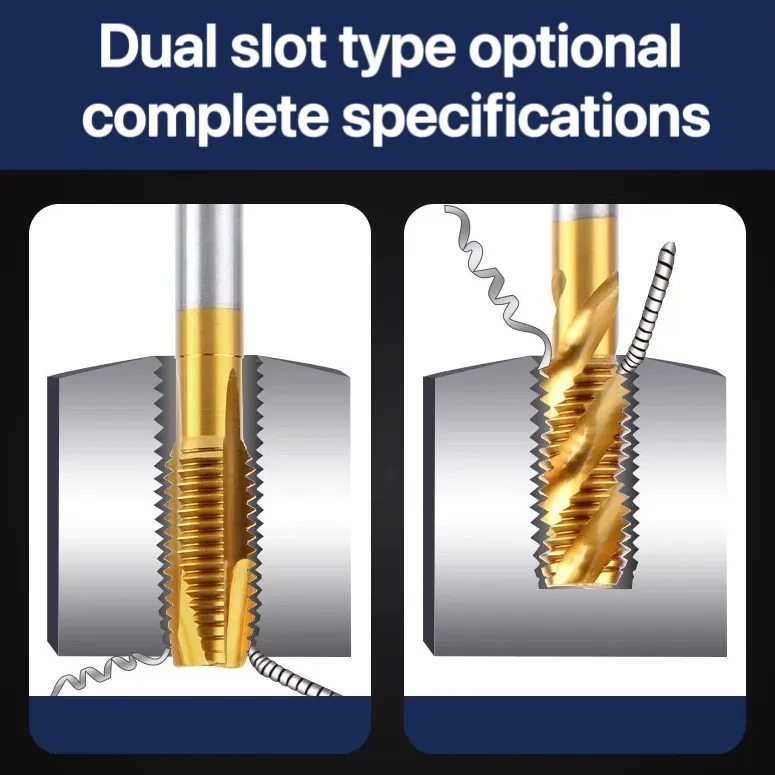

Spiral Flute tap

This premium TiN-coated spiral flute tap features a gold-colored titanium nitride coating, engineered for high-performance threading in stainless steel, titanium, and hardened alloys. Made from durable high-speed steel (HSS-E), its spiral flute design ensures efficient chip evacuation during CNC machining, lathe work, and manual applications. Ideal for through-hole threading in automotive parts, aerospace components, and industrial machinery manufacturing.

Product Specifications

| Material: | HIGH SPEED STEEL |

| Product Name: | Spiral Flute tap |

| Color: | Black or gold all have |

| Application: | Thread Cutting |

| Specification: | M1-M20 |

| Coating: | Nano tin coating black or Nano tin coating gold |

| Moq: | 10 pcs |

| Advantages: | High quality |

Products Advantages

key Features&Benefits

1. Advanced TiN Coating Technology

• Gold titanium nitride surface treatment increases hardness (up to 80 HRC)

• 3x longer tool lifespan vs uncoated taps

• Heat-resistant up to 600°C (1112°F)

2. Spiral Flute Design

• 45° helix angle minimizes chip clogging

• Perfect for blind/deep hole threading

• Reduced torque & breakage risk

3. Multi-Material Compatibility

• Optimized for 304/316 stainless steel, carbon steel, and Inconel

• Works with CNC machines, drill presses & hand tappers

4. Enhanced User Benefits

• Mirror-like golden finish for easy wear monitoring

• ISO 529/DIN 371 certified precision threads

FAQS

Company Advantage

• Since established, we have spent years of efforts in the development and production of the hardware. So far, we have mature craftsmanship and experienced workers to help us achieve a highly efficient and reliable business cycle

• Our global manufacturing and sales network have spread to and other overseas countries. Inspired by the high marks by the customers, we are expected to expand our sales channels and provide more considerate service.

• Our company has established a complete testing center and introduced advanced testing equipment. Our products not only meet the customer's quality requirements, but also have the advantages of reliable performance, no deformation, and durability.

• ATW CNC enjoys developed telecommunication and traffic convenience. The geographic location is superior and the natural conditions are good.

• ATW CNC provides excellent service for customers based on the principle of 'customer first'.

Thanks for visiting. If you have any other requests and questions, please contact ATW CNC.