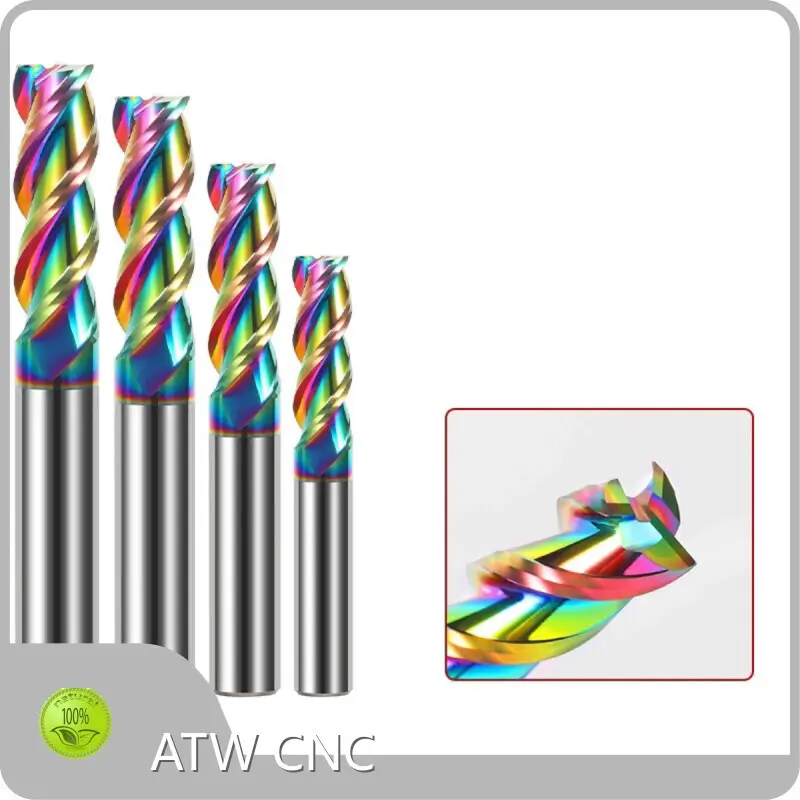

Engineered for high-efficiency CNC machining, our DLC Coated 3-Flute End Mill delivers superior performance in aluminum, brass, copper, and composite materials. Combining diamond-like carbon (DLC) coating with advanced carbide geometry, this tool minimizes friction, reduces heat buildup, and ensures exceptional chip evacuation, even at high speeds. Ideal for aerospace components, automotive parts, and electronic devices, it offers extended tool life and premium surface finishes, making it the go-to choice for precision industries.

General

Industry-specific attributes

|

Place of Origin

|

MADE IN CHINA

|

|

Brand Name

|

ATW CNC TOOLS

|

|

Certification

|

ISO Quality Mnagement System Certificate 9001 ISO Environmental Management System Certificate 14001

|

|

Minimum Order Quantity

|

10PCS

|

|

Packaging Details

|

One plastic pipe pack one piece, ten per group and carton outside.

|

|

Delivery Time

|

5-7 Days

|

|

Supply Ability

|

100,000

|

|

Material

|

Tungsten Solid Carbide

|

|

Coating

|

Nano TiSiN Coating

|

|

Other Attributes

|

|

Place of Origin

|

China

|

|

Warranty

|

3 years

|

|

Customized Support

|

OEM, ODM

|

|

Brand Name

|

ATW

|

|

Model Number

|

D10R1*D10*100L*4F

|

|

Material

|

Tungsten Solid Carbide

|

|

Product Name

|

Tungsten Solid Carbide Corner Radius Endmill 4F HRC56

|

|

Usage

|

CNC Milling Machining

|

|

Advantages

|

High Process Performance

|

|

After Warranty Service

|

Online support

|

|

Packaging and Delivery

|

|

PACKAGE

|

CARTON

|

1. ✨ WHY DLC COATING?**

✅ **2X Longer Life**: Ultra-hard DLC layer slashes wear, handles 10,000+ RPM effortlessly.

✅ **Zero Friction**: 40% lower friction coefficient vs. standard coatings—**no heat buildup, no gumming**!

✅ **Mirror Finish**: Achieve **Ra≤0.4μm** surface quality, perfect for aerospace & premium prototypes.

✅ **All-Day Durability**: Cut non-stop with 3-flute design + optimized chip evacuation.

|

Product name

|

55HRC tungsten solid carbide endmill

|

|

Product blade number

|

3 blades

|

|

Product coating

|

DLC coating

|

|

Suitable material

|

Aluminum alloy, copper alloy, acrylic

|

|

Suitable equipment

|

CNC machining center, engraving machine and other milling machines

|

Matters needing attention

Not suitable for processing aluminum alloy, plastic parts, key machine, hand drill, ordinary milling machine, please confirm the use of demand, if you have questions, please consult customer service, we will recommend you the right processing plan.

1. Buyers need to know the milling cutter and operating instructions Before using the tool, please measure the tool yaw. When the tool yaw accuracy exceeds 0.01mm, please correct it before cutting. 2. The shorter the length of the tool extension chuck, the better. If the tool extension is longer, it is necessary to reduce the speed, feed speed or cutting amount. 3. In the cutting, if abnormal vibration or sound is generated, please reduce the speed and cutting amount until the situation improves. 4. Steel cooling with spray and jet can improve the effect of milling cutter. 5. Note: It is not suitable for low-speed machines such as bench drill and electric drill.

1

What is the shipping method?

It could be shipped by sea,by air or by express(EMS,UPS,DHL,TNT,FEDEX and ect).

Please confirm with us before placing orders.

2

What is your lead time?

It depends on the order quantity and the season you place the order.Usually we can ship within 5-7 days for small quantity,

and about 30 days for large quantity.

With 15 years of industry expertise, ATW uses high-quality carbide materials to ensure tools with exceptional hardness, wear resistance, and heat resistance, suitable for both precision machining and heavy-duty tasks.

4

What are the advantages of us?

1. Extended Tool Life: Superior wear resistance reduces frequent replacements, lowering operational costs.

2. High-Speed Compatibility: Engineered for aggressive feed rates and RPMs, boosting productivity without compromising precision.

3. Exceptional Surface Finish: Razor-sharp edges and minimal vibration ensure smooth finishes and tight tolerances.

4. Versatility: Seamlessly transition between roughing and finishing across materials like aluminum, composites, and superalloys.

5. Cost Efficiency: Long-lasting durability maximizes ROl by minimizing tool expenditure and machine downtime.

5

How can I purchase ATW end mills?

Browse our official website catalog for direct orders, or contact our sales team for bulk pricing, technical specifications, and logistics support.

6

Are coating options available?

Yes. ATW offers coatings like TiAIN (Titanium Aluminum Nitride) to enhance heat resistance, reduce friction, and optimize performance in high-speed machining.

Contact ATW's experts for guidance on selecting the perfect tool for your application!

Company Advantages

· With a team of experts and the state-of-the-art technology, ATW CNC cnc milling cutter supplier is manufactured according to the requirements of lean production methods.

· A series of quality tests are conducted on the entire range to seek out any possible defect.

· DONGGUANG ULTRA MICRO HARDWARE MECHINERY CO.,LTD creates sales support for customers.

Company Features

· DONGGUANG ULTRA MICRO HARDWARE MECHINERY CO.,LTD is a specialist in the creation of cnc milling cutter supplier, all along the value chain from product development to manufacturing.

· DONGGUANG ULTRA MICRO HARDWARE MECHINERY CO.,LTD implements new technology to its business procedures.

· We are forward thinking, creative, flexible, and innovative in our approach to business. Call!

Application of the Product

The cnc milling cutter supplier produced by ATW CNC is widely used in industry.

ATW CNC can provide customers with one-stop solutions of high quality, and meet customers' needs to the greatest extent.