Buytriangle Carbide Inserts

Product details of the triangle carbide inserts

Product Information

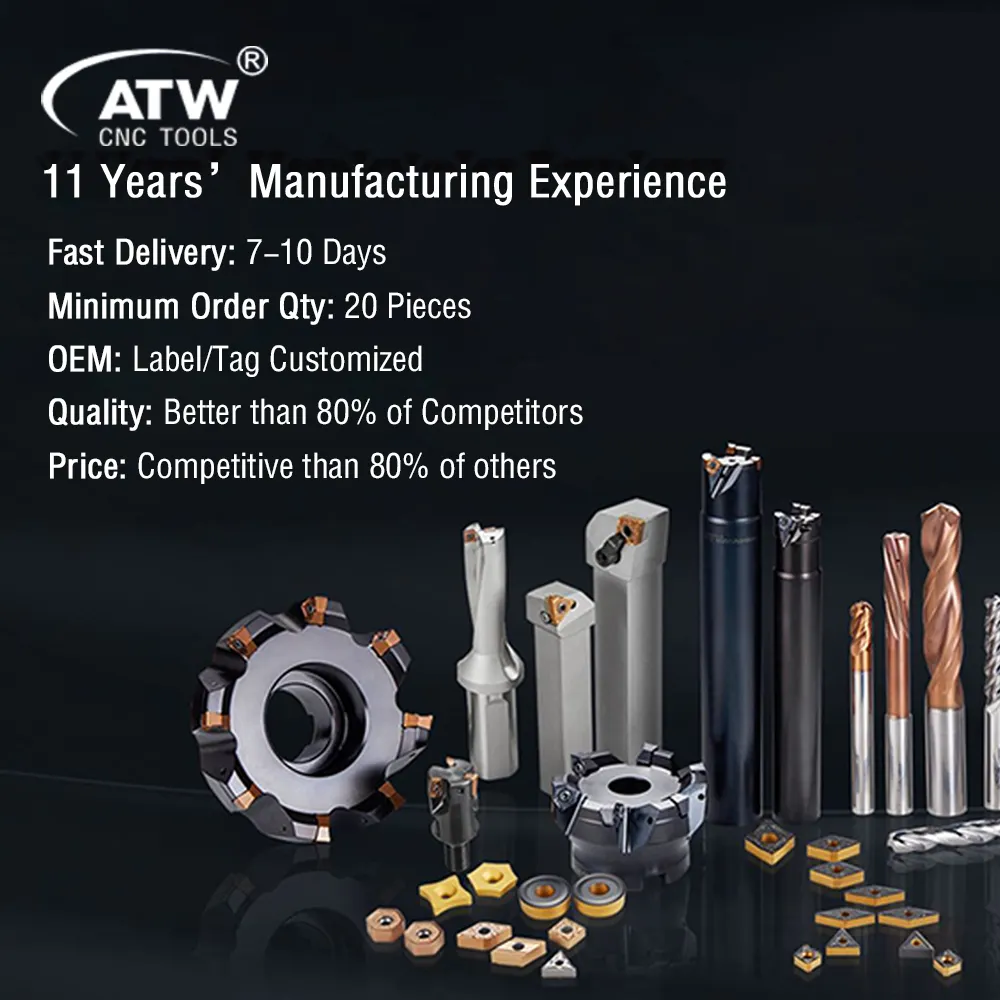

Our triangle carbide inserts designed for foreign customers are all unique and very successful. ATW CNC delivers high performance products that are cost-effective, customer-need specific. DONGGUANG ULTRA MICRO HARDWARE MECHINERY CO.,LTD can provide customers with personalized, diversified and systematic services.

Product Information

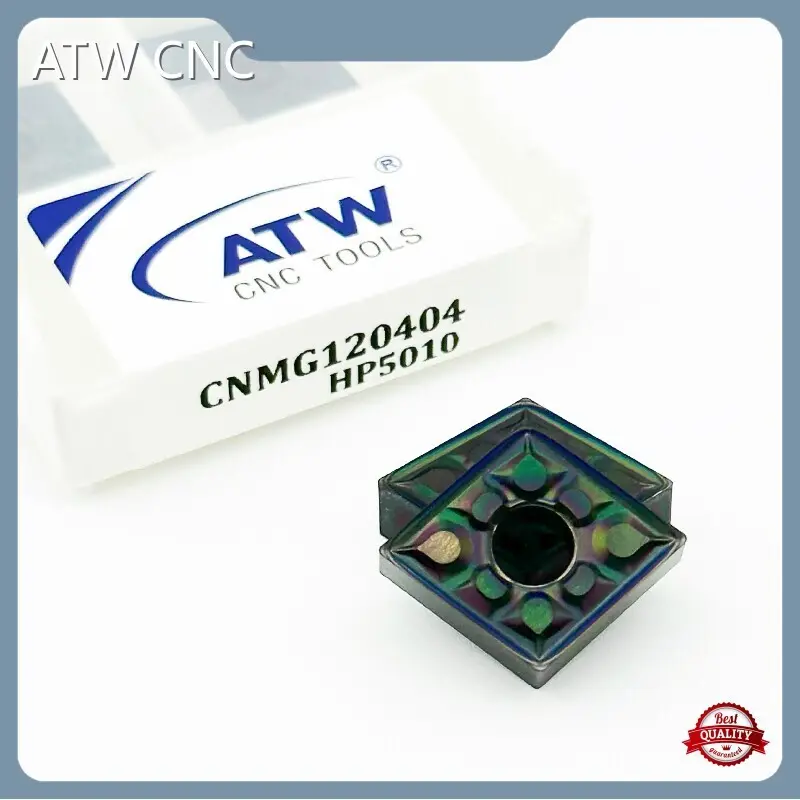

Engineered for high-efficiency CNC turning operations, our High-Performance Multicolor CNMG Carbide Inserts deliver exceptional results in machining hardened steel, stainless steel, and cast iron. These inserts combine cutting-edge PVD/CVD composite coatings with a robust tungsten carbide substrate to withstand extreme temperatures and pressures, ensuring extended tool life and reduced downtime. Ideal for automotive, aerospace, and heavy machinery applications, they excel in both roughing and finishing processes, providing superior surface finishes and reliable chip control.

Products Advantages

key Features&Benefits

1. Vibrant Multilayer Coatings: Proprietary coatings enhance thermal stability and wear resistance, reducing friction and extending blade life by up to 40% compared to standard inserts.

2. Extreme Hardness & Edge Retention: Rated for HRC 50-68, they tackle quenched steels, high-strength alloys, and heat-treated materials with precision and resilience.

3. Versatile Geometry: 80° diamond-shaped design with double-sided cutting edges offers 8 usable edges per insert, maximizing cost-effectiveness for external, internal, and face turning.

4. Optimized Chip Control: Customizable chipbreaker styles (TM, MA, HQ, PM) ensure consistent chip evacuation across varying depths of cut, preventing workpiece damage and improving process security.

5. Premium Material Quality: High-grade carbide formulation with reinforced toughness resists chipping and deformation under heavy loads, maintaining performance in high-pressure environments.

Product parameters

|

Specification |

CNMG120404 HP5010 |

|

Product |

Carbide Inserts |

|

Material |

Origin Tungsten Carbide |

|

Hardness |

HRC55 |

|

Coating |

Super Hard Nano PVD Coating |

|

Color |

Multi Color |

FAQS

Company Advantage

• Our company has a large production team to ensure timely delivery and complete variety of products to meet the needs of customers. Therefore, we can provide customers with the most professional custom services.

• Our hardware products are made of high quality materials. They have the advantages of abrasion resistance and good tensile strength. Besides, our products will be processed accurately and tested to be qualified before shipped out of factory.

• Since established, we have spent years of efforts in the development and production of the hardware. So far, we have mature craftsmanship and experienced workers to help us achieve a highly efficient and reliable business cycle

• We firmly believe that obtaining customer trust is based on the high-quality product and service, so we have set up a comprehensive service system and a professional customer service team. We are dedicated to solving problems for customers and meeting their demands as much as possible.

• Our global manufacturing and sales network have spread to and other overseas countries. Inspired by the high marks by the customers, we are expected to expand our sales channels and provide more considerate service.

As a professional manufacturer, ATW CNC is committed to producing high-quality, environmentally-friendly and durable CARBIDE ENDMILLS,CARBIDE INSERTS,DRILL BITS,HSS TAPS AND TOOL HOLDERS. We provide a wide range of products for you to choose and we have better discounts for larger-quantity orders. Please feel free to leave your contact information for business cooperation.