Carbide End Mill Bits D8*D8*60L*4F HRC56Precision Cutting

Product details of the carbide end mill bits

Quick Overview

ATW CNC carbide end mill bits is made by our skillful and experienced professionals. This product is superior to other products in performance and durability. The carbide end mill bits produced by ATW CNC is widely used in field for its excellent quality. The market share of the product is increased steadily, showing a promising application future.

Product Introduction

With a focus on quality, ATW CNC pays great attention to the details of carbide end mill bits.

Product Information

Tungsten carbide milling cutter is mainly used in CNC machining center, CNC engraving machine, suitable for high-speed machining.

ordinary milling machine: can be installed in the ordinary milling machine, used for processing hard and not complicated heat treatment materials.

tungsten steel flat-bottom milling cutter: suitable for high-speed precision surface milling, hard material processing performance is excellent.

end mill: good at plane, groove, step surface milling and copy milling, often used in finishing.

Tungsten steel milling cutter with high hardness and high wear resistance, widely used in carbon steel, alloy steel, cast iron and other processing.

Products Advantages

key Features&Benefits

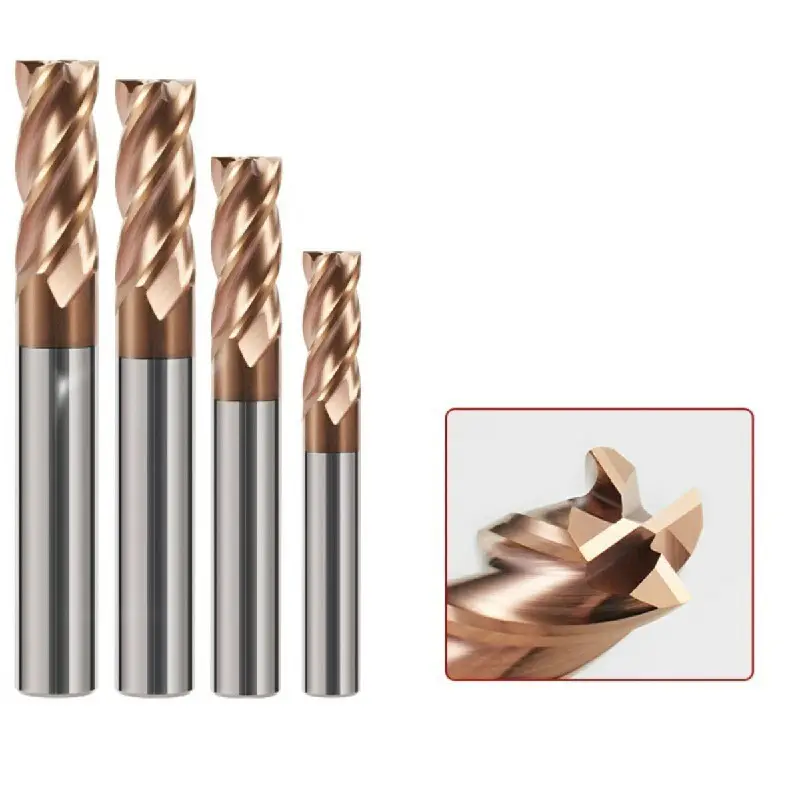

1. 4-Flute Design: Optimized for efficient material removal and smooth surface finishes in steel, stainless steel, cast iron, and non-ferrous alloys.

2. Bronze TIAIN Coating: Enhances heat resistance (up to 800°C), minimizes edge chipping, and ensures stability during high-speed machining.

3. Precision Geometry: Sharp cutting edges and helical flutes improve chip evacuation, preventing workpiece damage and reducing downtime.

4.Versatile Applications: Perfect for CNC milling, mold making, automotive parts, and so on.

Detail description

|

Place of Origin |

MADE IN CHINA |

|

Brand Name |

ATW CNC TOOLS |

|

Certification |

ISO Quality Mnagement System Certificate 9001 ISO Environmental Management System Certificate 14001 |

|

Minimum Order Quantity |

10PCS |

|

Packaging Details |

One plastic pipe pack one piece, ten per group and carton outside. |

|

Delivery Time |

5-7 Days |

|

Supply Ability |

100,000 |

|

Tungsten Solid Carbide |

|

|

Coating |

Nano TiSiN Coating |

|

Other Attributes |

|

|

Place of Origin |

China |

|

Warranty |

3 years |

|

Customized Support |

OEM, ODM |

|

Brand Name |

ATW |

|

Model Number |

D4_D4_50L_4F |

|

Material |

Tungsten Solid Carbide |

|

Product Name |

Tungsten Solid Carbide D4_D4_50L_4F |

|

Usage |

CNC Milling Machining |

|

Advantages |

High Process Performance |

|

After Warranty Service |

Online support |

|

Packaging and Delivery |

|

|

PACKAGE |

CARTON |

Detail description

FAQS

Company Information

With the location in dong guan, DONGGUANG ULTRA MICRO HARDWARE MECHINERY CO.,LTD is a high-tech enterprise integrating production, processing, sales and service. We are mainly engaged in CARBIDE ENDMILLS,CARBIDE INSERTS,DRILL BITS,HSS TAPS AND TOOL HOLDERS management. ATW CNC is always customer-oriented and devoted to offering the best products and service for each customer in an efficient manner. ATW CNC has a backbone team consisting of technical, production, quality inspection and other management personnel, which makes a strong guarantee for continuous growth. ATW CNC insists on providing customers with comprehensive solutions based on their actual needs, so as to help them achieve long-term success.

If you have any questions, feel free to consult us.