Cnc Carbide Tools Distributor

Company Advantages

· The production of ATW CNC cnc carbide tools is paid continuous and in-depth attention to meet customers' needs.

· The latest technology ensures cnc carbide tools's perfect product performance.

· Anytime you place order for our cnc carbide tools, we will make fast response and deliver at our earliest time.

Product Information

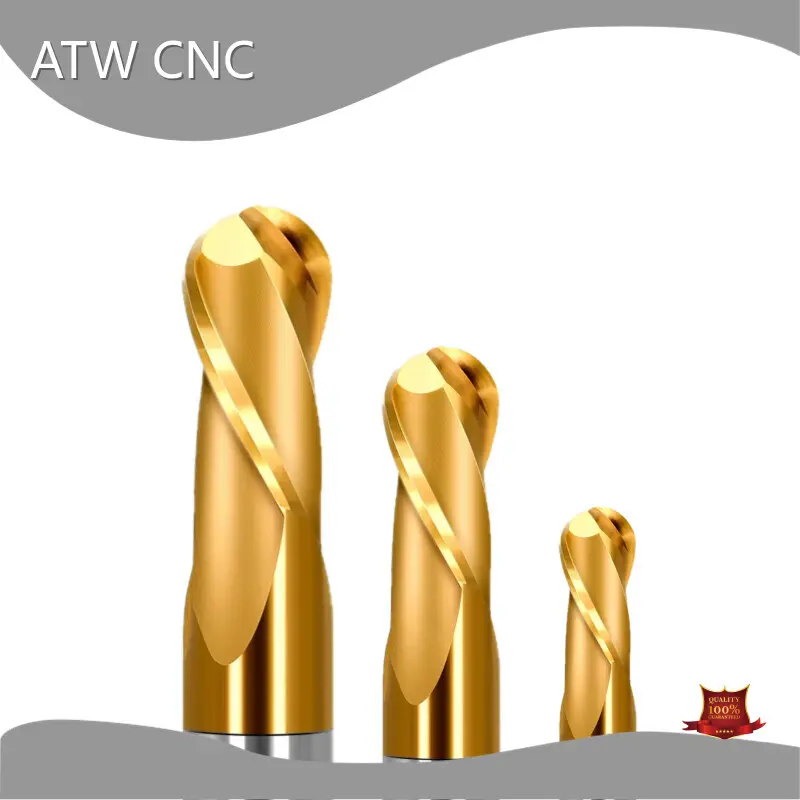

This 2-flute TiN-coated ball nose end mill is engineered for high-performance CNC machining, excelling in hardened steels (HRC50–65), titanium alloys, and aerospace materials. Featuring a micro-grain tungsten carbide substrate (0.4–1μm) and PVD TiN coating, it reduces friction by 35% and extends tool life by 30% compared to uncoated tools. The 30° helix angle minimizes vibration and enhances chip flow, ideal for high-speed operations up to 600m/min. Available in diameters from D0.5mm to D20mm with extended shank options (50L–150L), it supports deep cavity milling, 3D contouring, and precision engraving. Rigorously tested for ±0.01mm tolerance, it ensures Ra <0.2μm surface finishes, making it perfect for aerospace molds and automotive components. Dry cutting compatibility reduces coolant use, lowering operational costs by 20%.

Products Advantages

key Features&Benefits

1. Enhanced Durability: TiN coating combined with micro-grain carbide resists abrasion and high temperatures, doubling tool lifespan in dry cutting environments.

2. High-Speed Precision: Optimized geometry enables 25% faster feed rates while maintaining ±0.01mm accuracy, critical for aerospace molds.

3. Versatile Compatibility: Engineered for HRC50–65 materials, including stainless steel, SKD11, and titanium alloys, ideal for automotive and mold manufacturing.

4. Efficient Chip Control: Large flute capacity and tapered design prevent clogging, ensuring uninterrupted deep-pocket operations.

5. Cost Savings: Dry cutting compatibility reduces coolant costs by 20%, while extended tool life lowers replacement frequency by 40%.

Product parameters

|

Product name |

tungsten solid carbide end mill |

|

Product blade number |

2 blades |

|

Product coating |

TiN coating |

|

Suitable material |

45°~52° stainless steel |

|

Suitable equipment |

CNC machining center, engraving machine and other milling machines |

Details

User Instructions

1. Information Required by Buyers for Choosing Tools and Operating Instructions

2.Before using the tool, please measure the tool's deflection. If the deflection exceeds 0.01 mm, correct it before cutting.

3.The shorter the length of the tool extending out of the chuck, the better. If the tool extends too long, reduce the rotational speed, feed rate, or cutting volume.

4.During cutting, if abnormal vibrations or sounds occur, reduce the rotational speed and cutting volume until the situation improves.

5.For steel cooling, spray cooling or jet cooling is preferred, which can enhance the performance of the milling cutter.

FAQS

Company Features

· DONGGUANG ULTRA MICRO HARDWARE MECHINERY CO.,LTD offers the best cnc carbide tools at the best price. We are able to personalize our products in a unique style.

· DONGGUANG ULTRA MICRO HARDWARE MECHINERY CO.,LTD has both the technology and experience to make the top quality cnc carbide tools. ATW CNC hosts some of the world's leading researchers in cnc carbide tools field.

· Adhering to integrity to work and customers can win the trust of customers and development of ATW CNC. Get an offer!

Product Details

The specific details of cnc carbide tools are presented below.