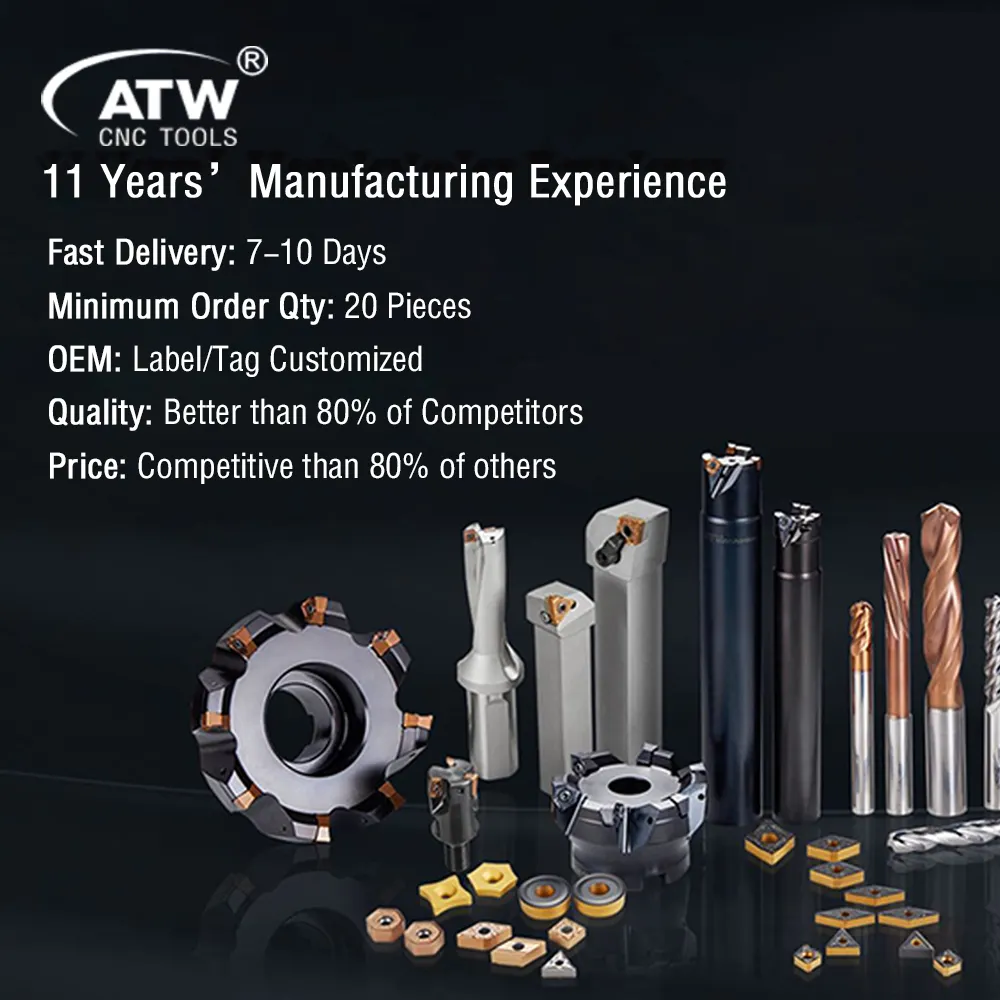

Factory Price Carbide Inserts Supplier Manufacturer

Product details of the carbide inserts supplier

Quick Overview

Many of carbide inserts supplier come from world-class designers. As a result of the effort, this product meets the strictest performance criteria. The carbide inserts supplier produced by ATW CNC can be used in many fields. DONGGUANG ULTRA MICRO HARDWARE MECHINERY CO.,LTD is strict with the quality of our products.

Product Information

carbide inserts supplier has the following advantages over other products in the same category.

Premium Cutting Tools for CNC Machining - Unleash Efficiency with Turning ,Tapping,U-Shaped,Milling inserts

Product Information——Milling inserts

Elevate your CNC milling performance with our premium colored milling inserts, offering 70% longer tool life and 40% faster cuts through advanced coating technologies. Available in 3 signature colors—gold TiAlN, bronze TiAlCrN, and black TiSiN—each insert is engineered for specific materials and applications. Crafted from ultra-hard tungsten carbide, these inserts deliver superior heat resistance, reduced friction, and exceptional chip control. Ideal for aerospace, automotive, and industrial manufacturing, they excel in high-feed roughing, semi-finishing, and finishing tasks.

Products Advantages

key Features&Benefits

1. Advanced TiAlCrN Coating

◦ Bronze-tinted TiAlCrN offers 60% longer tool life than standard TiAlN coatings.

◦ Withstands temperatures up to 1,100°C, perfect for high-speed machining.

2. Rapid Cycle Time Reduction

◦ 40% faster cuts at high-feed rates (0.35mm/tooth) for maximum productivity.

◦ Quick-release design enables blade replacement in under 20 seconds.

3. Unmatched Surface Quality

◦ Precision-ground edges achieve mirror finishes (Ra ≤ 0.6μm).

◦ Helical geometry reduces vibration for chatter-free operation.

4. Versatile Material Compatibility

◦ Works flawlessly on aluminum, steel, titanium, and inconel.

◦ Available in multiple geometries (square, round, triangular) for diverse tasks.

Product parameters

|

Specification |

RPMW1003MO NB6025 |

|

Product |

Carbide Inserts |

|

Material |

Origin Tungsten Carbide |

|

Hardness |

HRC55 |

|

Coating |

Nano Coating |

|

Color |

Bronze |

FAQS

Company Advantages

DONGGUANG ULTRA MICRO HARDWARE MECHINERY CO.,LTD has been concentrating on the design, manufacture, and marketing of carbide inserts supplier. We are highly prestigious for our strong capacities. Our factory is well-equipped. We continue to invest heavily in the latest equipment such as high-speed equipment, to ensure satisfying quality, capacity, time-to-market, and costs. Commitment to excellence is our goal and what we pursue. We encourage every one of our employees to improve themselves and cultivate professional knowledge using our company's resources. Therefore, we are competent to provide targeted services to clients. Inquire online!

Welcome to contact us.