Top Selling APMT Insert

Product details of the APMT insert

Product Description

The design of the structure makes APMT insert very easy to operate. The product is in line with international standards in performance, durability, usability and other aspects. The product is widely recognized and trusted by users and can meet continuously developing economic needs.

Premium Cutting Tools for CNC Machining - Unleash Efficiency with Turning ,Tapping,U-Shaped,Milling inserts

Product Information——Milling inserts

Elevate your CNC milling performance with our premium colored milling inserts, offering 70% longer tool life and 40% faster cuts through advanced coating technologies. Available in 3 signature colors—gold TiAlN, bronze TiAlCrN, and black TiSiN—each insert is engineered for specific materials and applications. Crafted from ultra-hard tungsten carbide, these inserts deliver superior heat resistance, reduced friction, and exceptional chip control. Ideal for aerospace, automotive, and industrial manufacturing, they excel in high-feed roughing, semi-finishing, and finishing tasks.

Products Advantages

key Features&Benefits

Engineered for extreme performance, the APMT1604 black carbide insert features a revolutionary TiAlN coating that delivers unrivaled heat resistance and wear protection. Designed for CNC milling machines, this insert excels in roughing and finishing operations on steel, cast iron, and stainless steel. Its optimized geometry ensures aggressive chip evacuation and reduced cutting forces, enabling higher feeds and speeds while maintaining superior surface quality.

Product parameters

|

Specification |

APMT1604PDER NB7025S |

|

Product |

|

|

Material |

Origin Tungsten Carbide |

|

Hardness |

HRC52 |

|

Coating |

Nano TiALSiN Coating |

|

Color |

Black |

FAQS

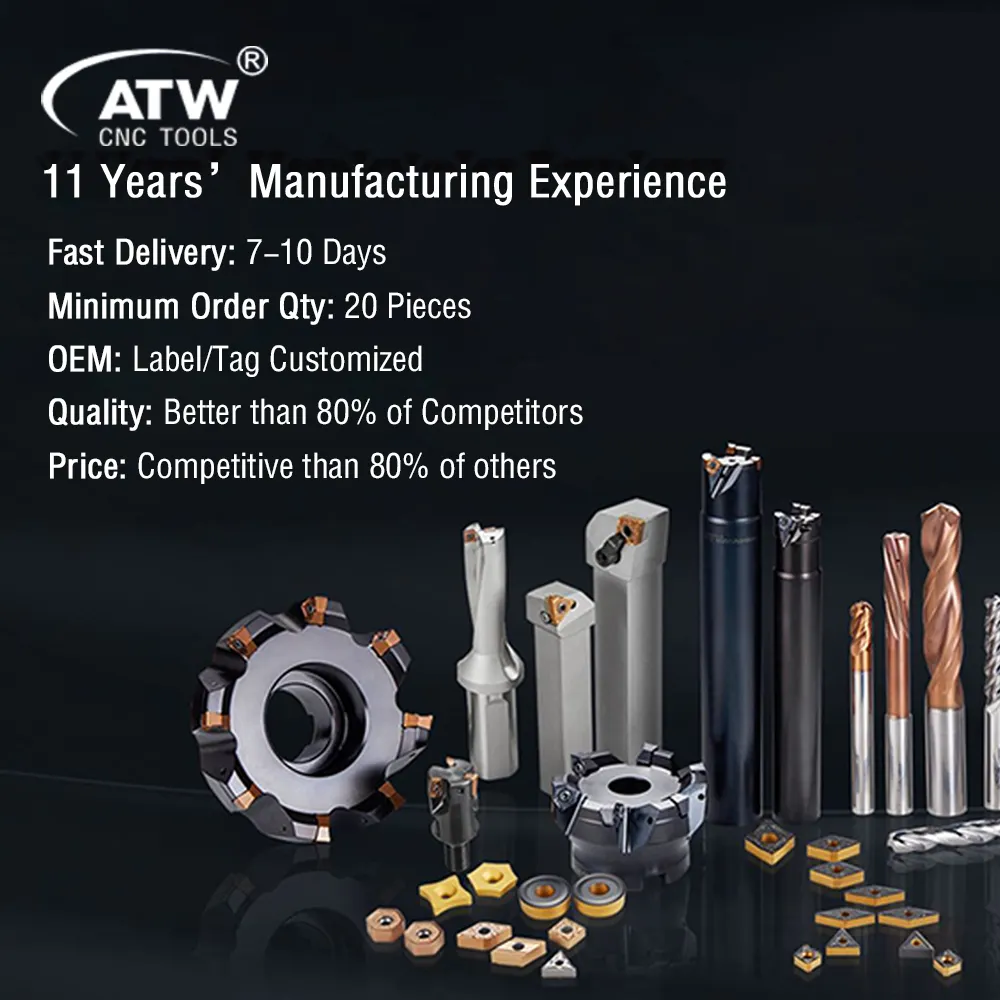

Company Feature

• Customers' needs are the foundation for ATW CNC to achieve long-term development. In order to better serve customers and further meet their needs, we run a comprehensive after-sales service system to solve their problems. We sincerely and patiently provide services including information consultation, technical training, and product maintenance and so on.

• Our company has established an excellent work team and our team members have rich industry experience. During the working process, we focus on efficiency and innovation. All that provides a significant force for our development.

• Since established, we have spent years of efforts in the development and production of the hardware. So far, we have mature craftsmanship and experienced workers to help us achieve a highly efficient and reliable business cycle

• ATW CNC is located in a place with traffic convenience. Besides, there are logistics companies leading to domestic and international markets. All these make an advantageous condition for the transportation of goods.

• Our hardware products are made of high-quality materials. After the complete production, they will undergo quality inspection. All this ensures the wear resistance, corrosion resistance and long service life of our hardware products.

Hello, thanks for your attention to this site! If you are interested in our products or services, please contact us. It is an honor for ATW CNC to receive your call and cooperate with you.