Top WCMT Insert Price List

Product details of the WCMT Insert

Product Information

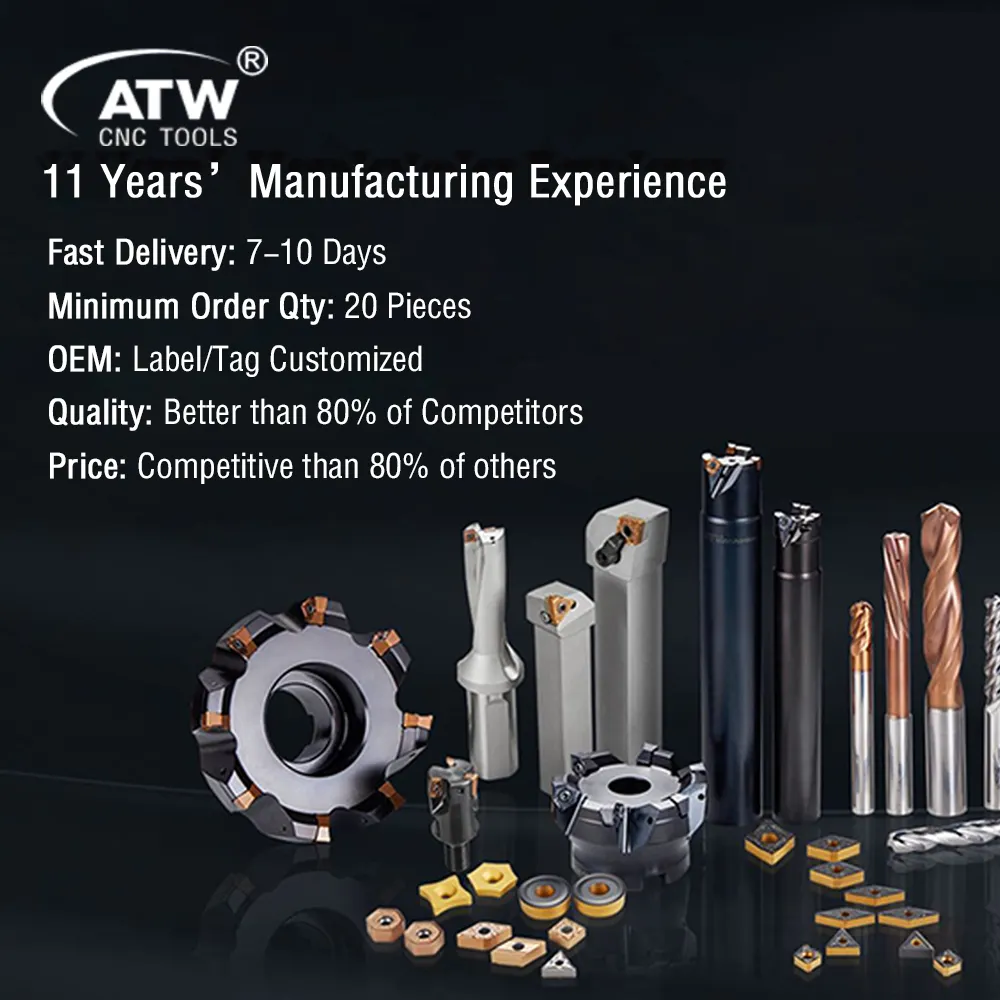

The production of ATW CNC WCMT Insert is based on the lean production principle. DONGGUANG ULTRA MICRO HARDWARE MECHINERY CO.,LTD has built and managed a team of professionals for WCMT Insert. DONGGUANG ULTRA MICRO HARDWARE MECHINERY CO.,LTD takes customers demand as center.

Product Information

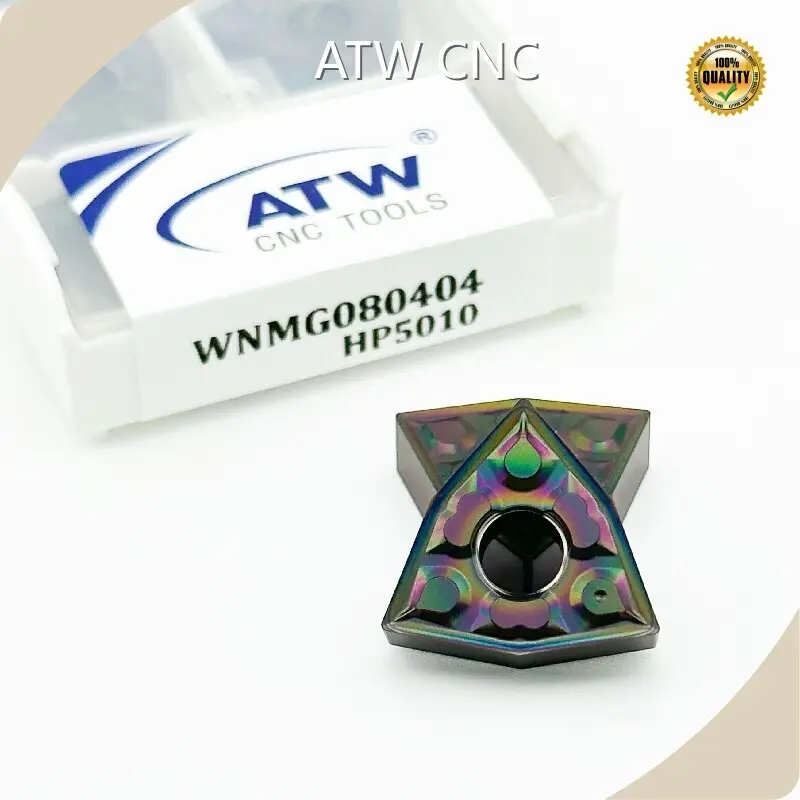

Designed for high-efficiency CNC turning operations, our High-Speed Multicolor WNMG Carbide Inserts deliver exceptional performance in machining quenched and tempered steels (HRC 50-68). These inserts combine cutting-edge PVD/CVD composite coatings with a premium tungsten carbide substrate to withstand extreme temperatures and pressures, ensuring extended tool life and reduced downtime. Ideal for automotive, aerospace, and heavy machinery applications, they excel in both roughing and finishing processes, providing superior surface finishes and reliable chip control.

Products Advantages

key Features&Benefits

1. Vibrant Multilayer Coatings: Proprietary PVD/CVD coatings enhance thermal stability and wear resistance, reducing friction and extending blade life by up to 40% compared to standard inserts. Specifically formulated for quenched steels, these coatings resist thermal cracking and maintain edge integrity.

2. Extreme Hardness & Edge Retention: Rated for HRC 50-68, they tackle high-strength alloys, heat-treated materials, and difficult-to-machine steels with precision and resilience.

3. Optimized Geometry for Quenched Steels: 80° diamond-shaped design with double-sided cutting edges offers 8 usable edges per insert, maximizing cost-effectiveness. Customizable chipbreaker styles (TM, MA, HQ, PM) ensure consistent chip evacuation even at high cutting speeds.

4. Premium Material Quality: High-grade carbide formulation with reinforced toughness resists chipping and deformation under heavy loads, maintaining performance in high-pressure environments.

Product parameters

|

Specification |

WNMG080404 HP5010 |

|

Product |

Carbide Inserts |

|

Material |

Origin Tungsten Carbide |

|

Hardness |

HRC55 |

|

Coating |

Super Hard Nano PVD Coating |

|

Color |

Multi Color |

FAQS

Company Advantage

• There are multiple traffic lines joining up in ATW CNC's location. The traffic convenience helps realize the efficient transportation of various products.

• Our global manufacturing and sales network have spread to and other overseas countries. Inspired by the high marks by the customers, we are expected to expand our sales channels and provide more considerate service.

• Since established, we have spent years of efforts in the development and production of the hardware. So far, we have mature craftsmanship and experienced workers to help us achieve a highly efficient and reliable business cycle

• Our hardware products are durable, practical and reliable. Moreover, they are not easy to get rusty and deformed. They can be widely used in various fields.

• ATW CNC provides strong guarantee for multiple aspects such as product storage, packaging and logistics. Professional customer service staff will solve various problems for customers. The product can be exchanged at any time once it is confirmed to have quality problems.

ATW CNC's quality-reliable CARBIDE ENDMILLS,CARBIDE INSERTS,DRILL BITS,HSS TAPS AND TOOL HOLDERS are available in a wide range of types and specifications. If you have any needs, please contact us quickly!