Topcarbide Cutting Tools SOLID TUNGSTEN CARBIDE 5-7 Days

Product details of the carbide cutting tools

Product Description

The appealing design of ATW CNC carbide cutting tools far exceeds the market average. This product has passed ISO and other international certification, quality is guaranteed. ATW CNC has been specialized in providing the professional service about carbide cutting tools.

Product Information

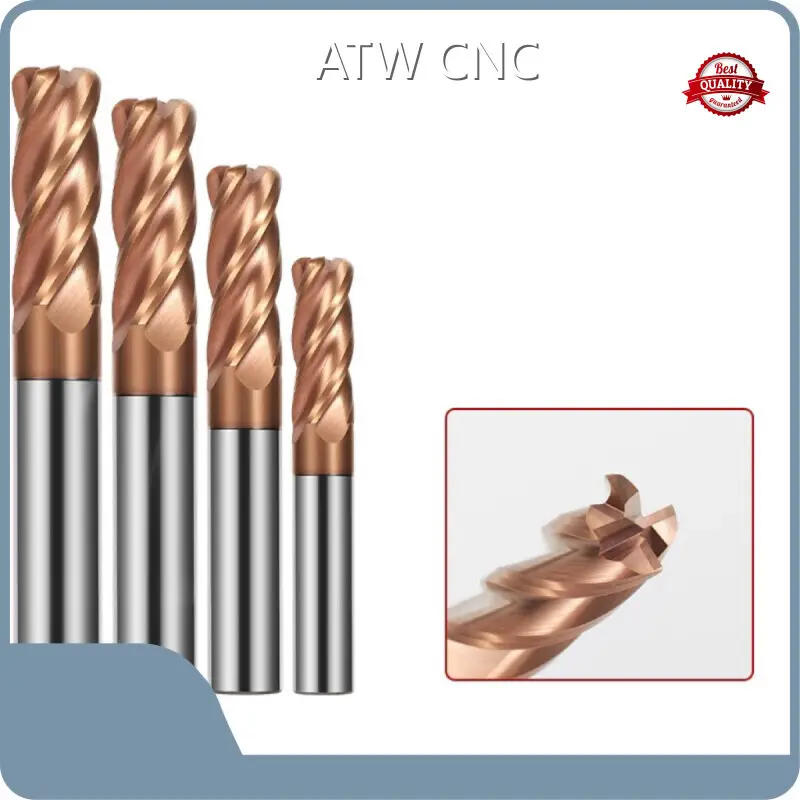

Premium 4 Flute Bronze-Coated

Tungsten Carbide Ball Nose End Mill Engineered for high-performance machining, this 4-flute ball nose end mill combines cutting-edge technology with rugged durability. Crafted from ultra-fine grain tungsten carbide and enhanced with a bronze TiAIN coating, it delivers exceptional heat resistance (up to 800°C) and wear resistance, extending tool life by 50% in demanding applications like hardened steel (HRC62), mold steel (SKD-11, S136), and alloy machining

Products Advantages

key Features&Benefits

1. 4-Flute Ball Nose Design: Optimized for high-speed CNC milling, providing smooth finishes on complex contours, 3D profiling, and slotting. The R-corner geometry reduces chipping and ensures precision in mold making and automotive parts.

2. Bronze TiAIN Coating: Advanced heat-resistant layer minimizes friction, prevents edge degradation, and supports dry or wet machining conditions. Ideal for high-efficiency material removal at small depths of cut .

3. High Rigidity & Stability: Negative rake angle and reinforced helical flutes enhance rigidity, reducing vibration during heavy-duty cutting. Short flute length design maximizes tool strength for hardened materials.

4. Cost-Effective Performance: Achieve 2x higher metal removal rates compared to standard end mills, reducing production time and tooling costs.

Detail description

|

Place of Origin |

MADE IN CHINA |

|

Brand Name |

ATW CNC TOOLS |

|

Certification |

ISO Quality Mnagement System Certificate 9001 ISO Environmental Management System Certificate 14001 |

|

Minimum Order Quantity |

10PCS |

|

Packaging Details |

One plastic pipe pack one piece, ten per group and carton outside. |

|

Delivery Time |

5-7 Days |

|

Supply Ability |

100,000 |

|

Tungsten Solid Carbide |

|

|

Coating |

Nano TiSiN Coating |

|

Other Attributes |

|

|

Place of Origin |

China |

|

Warranty |

3 years |

|

Customized Support |

OEM, ODM |

|

Brand Name |

ATW |

|

Model Number |

D4_D4_50L_4F |

|

Material |

Tungsten Solid Carbide |

|

Product Name |

Tungsten Solid Carbide D4_D4_50L_4F |

|

Usage |

CNC Milling Machining |

|

Advantages |

High Process Performance |

|

After Warranty Service |

Online support |

|

Packaging and Delivery |

|

|

PACKAGE |

CARTON |

Detail description

FAQS

Company Advantage

• Our company has a creative team with wide knowledge and the ability of mold opening and production. Therefore, we can provide customers with professional custom services.

• Since established, we have spent years of efforts in the development and production of the hardware. So far, we have mature craftsmanship and experienced workers to help us achieve a highly efficient and reliable business cycle

• Our global manufacturing and sales network have spread to and other overseas countries. Inspired by the high marks by the customers, we are expected to expand our sales channels and provide more considerate service.

• Our company has advanced production equipment and superior production lines. In addition, there are perfect testing methods and quality assurance system. All this not only guarantees a certain yield, but also ensures the excellent quality of our products.

• ATW CNC always keeps in mind the service principle of 'customer's needs can not be ignored'. We develop sincere exchanges and communication with customers and offer them comprehensive services in accordance with their actual demands.

ATW CNC's CARBIDE ENDMILLS,CARBIDE INSERTS,DRILL BITS,HSS TAPS AND TOOL HOLDERS are of high quality and affordable price. If you have any needs, please contact us. We are looking forward to reaching cooperation with you.