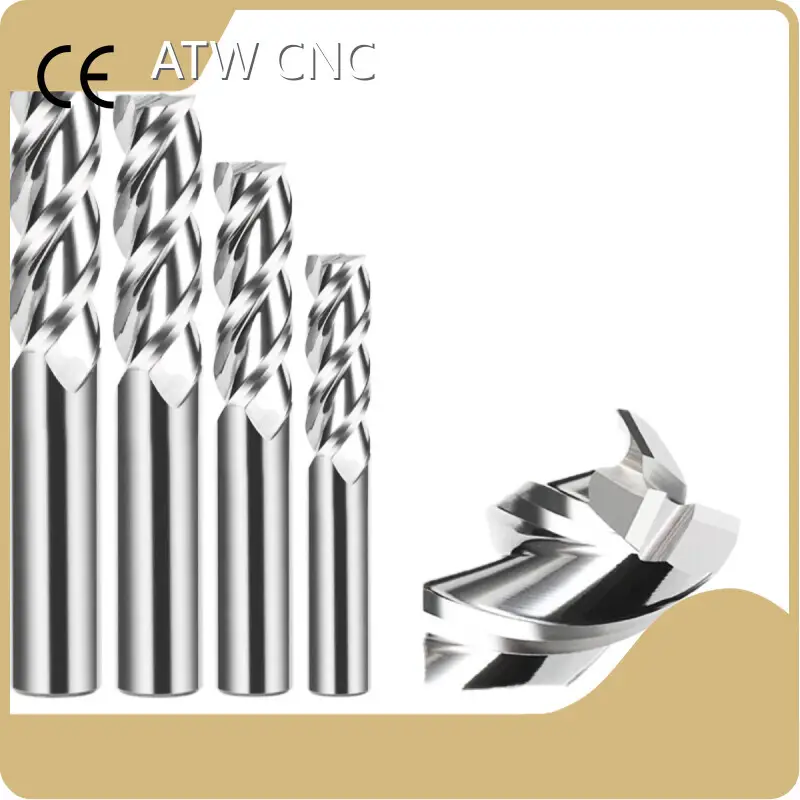

Tungsten Carbide End Mill Φ8*D8*60L*3FMaker

Product details of the tungsten carbide end mill

Quick Detail

The appearance of ATW CNC tungsten carbide end mill looks very attractive. An appropriate programmed of quality control (qc) must be implemented in its production. ATW CNC's tungsten carbide end mill can be used in a variety of situations. This product has achieved good results in practical applications.

Product Introduction

With a focus on product quality, ATW CNC pursues perfection in every detail.

Product Information

This 3-flute carbide end mill is specifically engineered for high-efficiency aluminum machining, offering exceptional surface finishes (Ra ≤0.25um) and reduced tool wear. Featuring a 45° helix angle and polished spiral flutes, it ensures smooth chip evacuation even in deep cavity and slotting applications. Compatible with CNC machines, it delivers precision for aerospace components, automotive parts, and mold manufacturing. Available in diameters from 3mm to 32mm, with custom tolerance options (H6 shank, $0.02mm blade precision)

Products Advantages

key Features&Benefits

1. Superior Aluminum-Specific Design

• Anti-Adhesion Coating: Reduces aluminum buildup with specialized surface treatments (e.g., high-gloss composite coatings) for clean cuts.

• Optimized Geometry: 3-flute design balances material removal rate and tool rigidity, ideal for soft alloys like 6061-T6 and silicon-aluminum composites.

2. Enhanced Performance Features

• Polished Flutes: Minimizes friction and prevents chip welding, extending tool life by 30% compared to standard mills.

• High-Speed Compatibility: Supports

RPM up to 18,000 for rapid machining without compromising finish quality.

3.Multi-Industry Versatility

• Applications: Aerospace structural parts, smartphone casings, automotive molds, and renewable energy components .

• Material Range: Effective for aluminum (Si <9%), copper alloys, and composite materials

Detail description

|

Place of Origin |

MADE IN CHINA |

|

Brand Name |

ATW CNC TOOLS |

|

Certification |

ISO Quality Mnagement System Certificate 9001 ISO Environmental Management System Certificate 14001 |

|

Minimum Order Quantity |

10PCS |

|

Packaging Details |

One plastic pipe pack one piece, ten per group and carton outside. |

|

Delivery Time |

5-7 Days |

|

Supply Ability |

100,000 |

|

Tungsten Solid Carbide |

|

|

Coating |

Nano TiSiN Coating |

|

Other Attributes |

|

|

Place of Origin |

China |

|

Warranty |

3 years |

|

Customized Support |

OEM, ODM |

|

Brand Name |

ATW |

|

Model Number |

D4_D4_50L_4F |

|

Material |

Tungsten Solid Carbide |

|

Product Name |

Tungsten Solid Carbide D4_D4_50L_4F |

|

Usage |

CNC Milling Machining |

|

Advantages |

High Process Performance |

|

After Warranty Service |

Online support |

|

Packaging and Delivery |

|

|

PACKAGE |

CARTON |

Detail description

Detail description

FAQS

Company Introduction

DONGGUANG ULTRA MICRO HARDWARE MECHINERY CO.,LTD is a front-runner in the tungsten carbide end mill industry for the considerate customer service and exceptional products. Our company has a strong technical base. Our R&D team is skilled and experienced with abundant expertise in the tungsten carbide end mill industry. They help our company keep competitive in the market through continuous product innovation. DONGGUANG ULTRA MICRO HARDWARE MECHINERY CO.,LTD aims to create a famous brand with high efficiency, high quality and excellent service. Please contact us!

We supply our products of good quality and affordable price in long term. Please feel free to consult us!