Tungsten Inserts Superior Wear Resistance

Product Information

WNMG080404 Dual-Coated Carbide Inserts

The WNMG080404 is a high-performance, double-sided carbide insert engineered for precision CNC turning and industrial machining applications. Featuring advanced dual-coating technology (TiAlN + AlTiN), these inserts deliver exceptional wear resistance and thermal stability, making them ideal for machining stainless steel, hardened alloys, and high-temperature materials. The unique chipbreaker design ensures optimal chip control and reduced vibration, enhancing surface finish and extending tool life in high-speed operations. Compatible with both external and internal turning tasks, these inserts are widely used in automotive, aerospace, and heavy machinery industries for their durability and cost-effectiveness.

Products Advantages

key Features&Benefits

WNMG Dual-Coated Carbide Inserts deliver unmatched performance for CNC turning and industrial machining, combining cutting-edge technology with cost-saving efficiency.

Featuring advanced TiAIN + AITiN dual coatings, these inserts excel in extreme conditions, offering 30% longer tool life compared to conventional options. The nano-layered PVD coatings provide exceptional heat resistance (up to 900°C) and reduced friction, optimizing performance on stainless steel, hardened alloys, and cast iron. Enhanced

chipbreaker geometry guarantees smooth chip evacuation, eliminating entanglement and vibration for ultra-precise surface finishes even in high-speed applications(150-350 m/min).

Product parameters

|

Specification |

WNMG080404 HP6120 |

|

Product |

Carbide Inserts |

|

Material |

Origin Tungsten Carbide |

|

Hardness |

HRC55 |

|

Coating |

Double Color Coated CVD |

|

Color |

Double Color |

FAQS

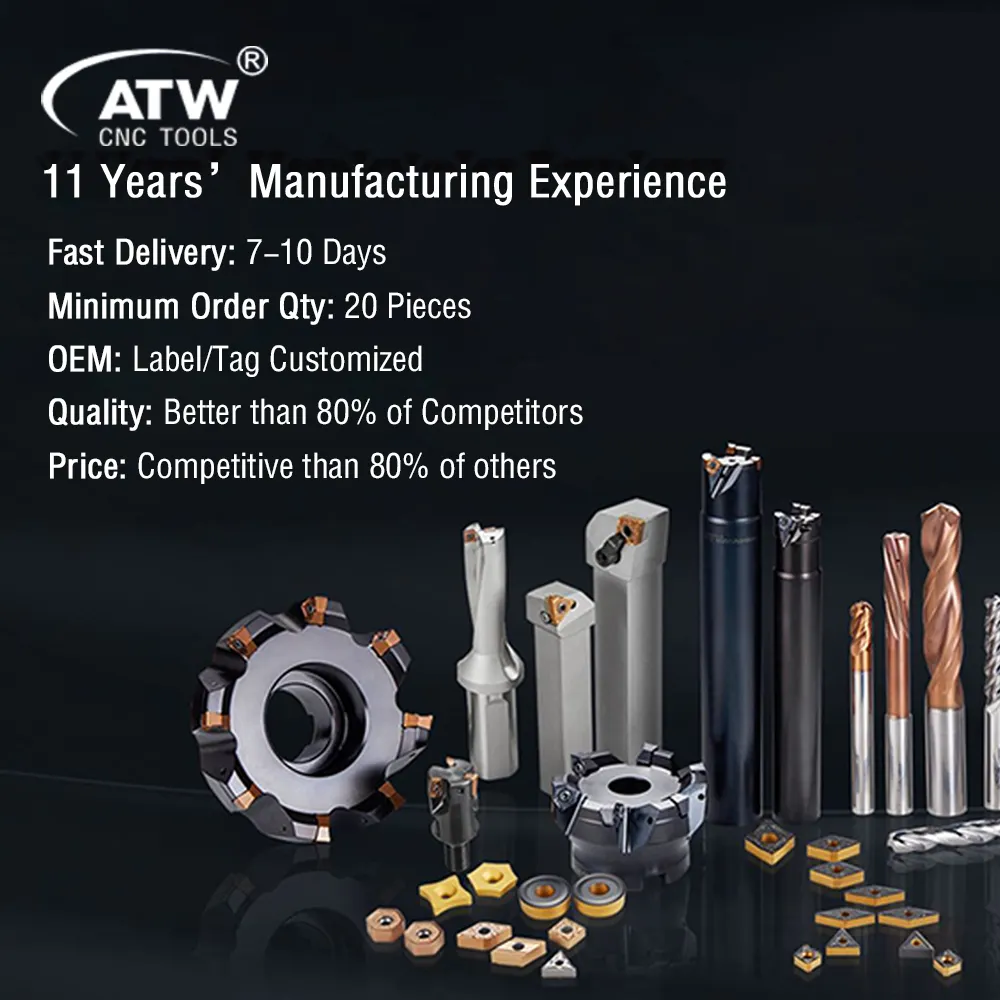

Company Advantages

· ATW CNC tungsten inserts is designed by a professional design team which has been putting efforts into designing.

· The performance index of this product is in the domestic leading position.

· The product is now widely available in a wide range of industries and has a wide range of applications.

Company Features

· With a unique vision, DONGGUANG ULTRA MICRO HARDWARE MECHINERY CO.,LTD is a leader in providing high quality tungsten inserts and services.

· Our technical support engineers have deep industry and technical knowledge of tungsten inserts.

· Technological strength is so crucial for us to become stronger. Hence, we have set up a clear growing objective, that is to gain a technological advantage over competitors.

Application of the Product

ATW CNC's tungsten inserts is widely used in many industries.

ATW CNC insists on providing customers with comprehensive solutions based on their actual needs, so as to help them achieve long-term success.